Cutting Devices

-

Dive Rite Trauma Shears$32.00

Dive Rite Trauma Shears$32.00 -

OMS Sea Snips w/ Sheath$20.00

OMS Sea Snips w/ Sheath$20.00 -

DGX Titanium EMT Shears$8.00

DGX Titanium EMT Shears$8.00

StainLESS does not mean StainPROOF

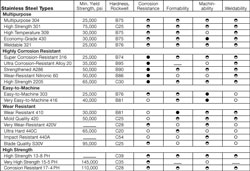

A common misconception among divers is that stainless steel does not corrode at all. There are various types of stainless steel, each with different corrosion properties, that make a specific grade more or less suited to a particular application. Because there is no perfect stainless steel, the selection of the grade is often a compromise between corrosion resistance and malleability. Stainless grades selected because they hold a sharp cutting edge will corrode relatively fast compared to other grades. The most corrosion resistant grades are not usually a good choice for bolt snaps and hand tools because depending on the use application they may not offer the best wear resistance or may be too brittle.

Stainless steel can be treated to form a chromium oxide protective layer on the surface of stainless steel using a chemical immersion process that will also simultaneously remove any free iron from the surface. This process, known as passivation, is routinely applied to marine grade stainless steel products used in diving. The resulting clear, almost invisible, layer of chromium oxide prevents corrosion by stopping oxygen from reaching the underlying metal. This allows it to withstand damage from corrosives including many acids, bases, and detergents, as well as salt water. However, depending on environmental conditions you may notice some surface 'stains' that can form on various stainless items. In general these are cosmetic in nature and we recommend you allow the cosmetic stains to remain when practical. Using an abrasive is likely to remove the invisible corrosion resistant film, allowing corrosion to spread and ultimately making the corrosion worse.

StainLESS does not mean StainPROOF and all diving products made of stainless steel must receive some basic care to help minimize corrosion. Rinse any stainless steel components in dive equipment with fresh water after diving or when otherwise in contact with salt water, allow them to dry and do not store them in damp or moist environments. Make sure any storage sheath or pouch is also rinsed and allowed to dry before returning the stainless item to the pouch. When rinsing bolt snaps, be sure to work the bolt action several times to eject any saltwater trapped in the slider and spring mechanism. In particular, avoid storing stainless steel near or in contact with other metals having strongly dissimilar electropotentials, especially aluminum, such that moisture can induce galvanic corrosion. In cases of galvanic corrosion where the stainless item is in close proximity to some types of metals, rust or other color stains will electrolytically transfer to the surface of the stainless item.

Click on the graphic to see a table of some stainless grades and their properties

- Hardness - As hardness increases, metals become more wear resistant but they may be less malleable. Some types of stainless steel harden by cold working, and others can be heat treated. The 300 series hardens by cold working, many in the 400 series can be hardened by heat treating.

- Formability - Stainless steel is generally formable and bendable, but types that harden by cold working can require more force to bend than carbon steel.

- Machinability - During machining, stainless steel can become gummy and stick to cutting tools, making it typically more difficult to machine than steel.

- Weldability - Take care to clean stainless steel before and after welding operations. Contaminants, such as lubricants and particles from grinding tools, will reduce corrosion resistance at welded points.

- Finish - Stainless steel does not always have a shiny finish. In fact, stainless steel is available in a number of finishes, ranging from an unpolished, dull surface to a reflective mirror-like shine.