DGX Premium Doubles Bands Set w/Bolts

- Marine grade 304 SS bands are (TIG) welded, passivated w/ deburred edges

- Set includes two bands with two bolt assemblies

- 5/16-18 all-thread headless bolts fit ANY backplate

- Standard 8.5-inch center to center manifold spacing

- Bands are {2.5 in | 6.4 cm} wide with polished satin finish

DGX Premium Doubles Bands Set w/Bolts

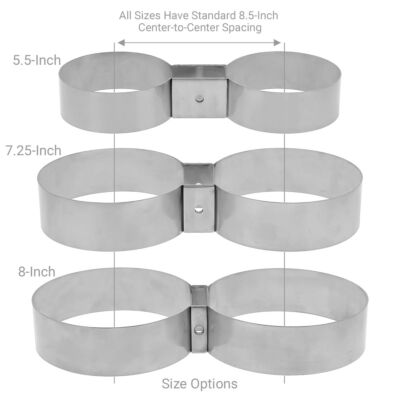

LOOK CAREFULLY, we offer three different sizes on the bands to fit different cylinder diameters, it is easy to make a mistake when ordering. If you are not sure what your cylinder diameter is, see the chart below.

The set of two heavy-duty Premium Doubles Bands are constructed of 304 stainless steel, with a polished satin finish. They are tungsten inert gas (TIG) welded, passivated, and have deburred edges that minimizes scratching tanks during assembly. Available in three different sizes to fit a variety of different cylinder diameters, all three sizes have bands that are {2.5 in | 6.35 cm} wide.

All the bolts, nuts and washers included in the kits with these bands are also made of stainless steel. The 5/16-18 all-thread headless bolts allow you to precisely adjust the bolt height to perfectly fit any brand or size of backplate and wing assembly. The aircraft nuts are 1/2-inch across the flats, but the hex nuts are the next size larger at 9/16-inch. Using two different sized nuts with the same threads allows the convenience of using a single set of wrenches for assembly.

Assembling a set of doubles is easy if you follow the DETAILED ASSEMBLY INSTRUCTIONS we provide.

Choose the Appropriate Size Tank Bands for Your Cylinders

| Size | Cylinders | Remarks |

| 5.5 in | AL30, AL40, LP45, LP50 | The 5.5-inch bands are used with aluminum AL40's and steel LP50's. For metric cylinders use the 5.5-inch bands on the 7L and 5L cylinders. |

| 6.7 in | MP71, FX71, most early 2250 psi steel cylinders | Unfortunately, we currently do not have a source for bands to fit 6.7-inch cylinders such as the early 2250 psi cylinders and PST steel LP72's, as well as the modern Faber MP71's and FX71's. |

| 7.25 in | AL72, AL80, LP80, LP85, All HP E7/X7/F7's | The 7.25-inch bands fit the most common diameter cylinders such as aluminum AL80s or steel LP80's, HP80's, HP100's, and HP120's. The 7.25-inch bands also fit the 7.0-inch diameter LP85's and the 6.9-inch diameter AL72's. For metric cylinders use the 7.25-inch bands on 12.2L, 10.5L and 9L cylinders. |

| 8 in | AL100, LP95, LP104, LP120, All HP E8/X8/F8's | The 8.0-inch bands fit the larger diameter cylinders such as aluminum 100's or steel LP95's, LP104's, HP117's and HP133's. For metric cylinders use the 8-inch bands on 18L and 15L cylinders. |

| Brand | DGX |

|---|---|

| SKU | DX-7055xx |

| Weight | 5.000000 |

Customer Reviews

YOU MAY ALSO BE INTERESTED IN THE FOLLOWING PRODUCT(S)

Evolution of Manifolds and Bands

In the early 1980's there were few double tank manifolds available. Divers had a choice of a dual outlet metal-to-metal seal manifold from one manufacturer or a single outlet double barrel o-ring seal manifold from another manufacturer. Manifolds during this period did not have crossbars with isolation valves. The center-to-center spacing on these manifolds was for the 6.7-inch diameter steel 72s and the 7.25-inch aluminum 80s, which was tight for the increasingly popular 8-inch diameter steel 95s and 104s. The tight spacing meant bolts could rub against the tanks and the bands were prone to gapping.

In the late 1980s, more dual outlet manifolds became available with several choices for seal design and centers spacing. Specialty band manufacturers also entered the market and offered a variety of band sizes and types for use with different manifolds and tanks. Some manufacturers used tack welds that would allow the bands to flex in accordance with the size of the tank, rather than manufacture multiple sets of bands. The tack weld approach required care during assembly because the welds would separate if the assembler were to over-torque the bolts.

By the 1990s, valve manufacturers began to standardize manifold centers spacing and isolation valve crossbars became the norm. The double barrel seal manifold became the preferred design, providing better shock absorption and redundancy over the metal-to-metal seal manifolds. Tack welded bands became obsolete, the tack welds replaced by rigid structural plates.

Today, the new generation adjustable 8.5-inch center-to-center spacing manifolds provide up to 0.25-inch of adjustability so that tank bands fit properly even when there are minor variations in tank dimensions. If you have a manifold with double o-ring seals and adjustable spacing, you should not need a specialized tank band. Our article Assembling Double Cylinders makes it easy.